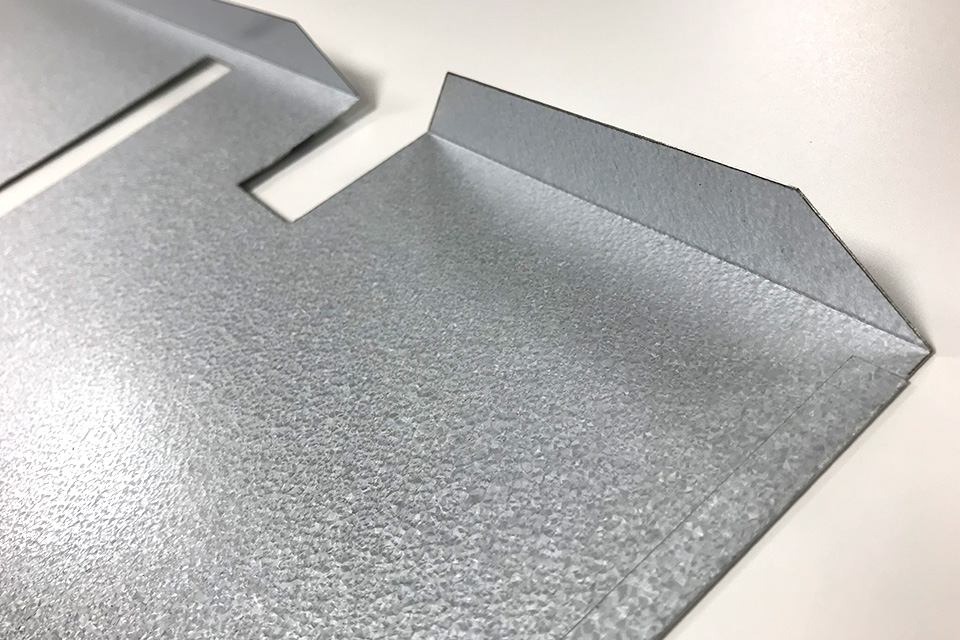

Hard lagging

This is a conventional racking method, which keeps heat within a heat insulating material and a metal material.

It is suitable for insulation work where there is sufficient space or where regular maintenance is not required. Since it can be produced at a relatively low cost, it tends to be very cost-effective.

Furthermore, in addition to conventional site construction work, we have devised a new racking method that can also be used for advanced arrangements and mass production. We continue to make improvements every day in order to aim for a racking method that anyone can handle.

Typical installation example and precautions for conventional racking work

Also, since the racking material is metal, it may corrode due to ageing, so it is necessary to carry out periodic inspections and repairs.

* Please note that if you do not have specialized knowledge for inspection and repair, the original performance may not be maintained.

Proposing the new hard lagging style

However, there are processes that cannot be adjusted by the customer, such as schedules for specialists, which can hinder smooth production planning and process management. We are developing a module-style racking construction that allows customers to make their own production plans to eliminate these external factors.

By selecting the necessary racking points in advance and designing the modules, advanced arrangements and parallel arrangements can be made and the requirement for specialists on-site can be reduced. Since it has already been designed, it is possible to manage by using drawings and part numbers, which can be used for mass production and then can be installed by the customer.

You can look forward to ongoing product developments and quality improvements every day and we are making continuous progress towards meeting ongoing market requirements.

Hybrid type can also be provided

Please refer to the Hybrid page for details.