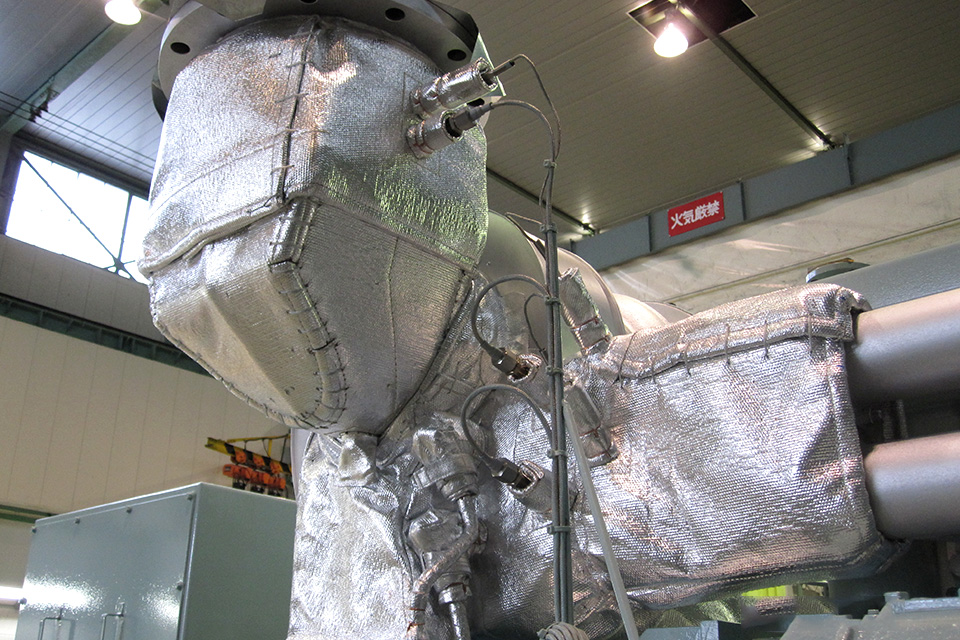

Soft lagging

This is a precise lagging method for marine diesel engine turbines, exhaust pipes, air supply pipes, fuel pipes, etc. in accordance with SOLAS regulations, utilizing our unique technology and know-how.

This construction method is effective for all high temperature parts, and we can respond to various requirements and shapes flexibly and with a short delivery time.

It is also extremely effective in preventing oil splashes, enhancing safety and improving overall energy efficiency.

Thermal insulation /Heat insulation

For ship owners operating on mainly overseas routes, the convention stipulates that “all parts with a surface temperature of 220 ℃ or higher must be properly insulated”. Our products comply with SOLAS regulations.

In addition, it is a product, which exhibits sufficient properties in terms of ensuring safety and improving energy efficiency for use on land and generator use.

In addition, it is a product, which exhibits sufficient properties in terms of ensuring safety and improving energy efficiency for use on land and generator use.

Work efficiency and economy

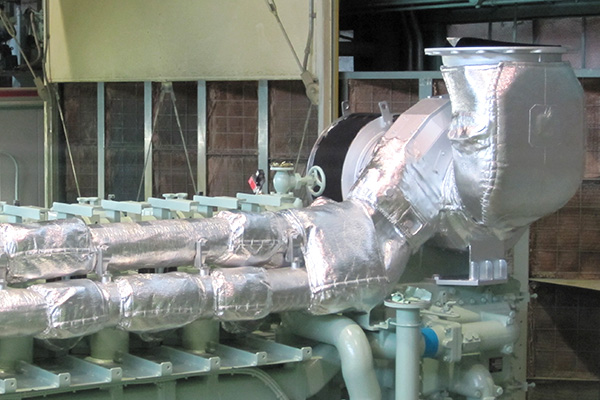

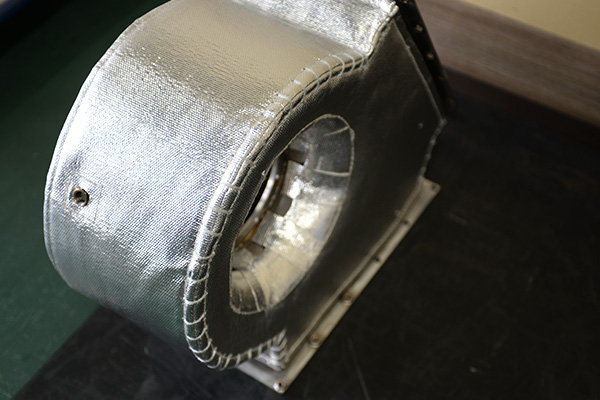

In the past, complicated parts such as exhaust pipes and fuel pipes had to be constructed simply due to the surrounding clearance problem. However, with our lagging, it is possible to insulate with a higher degree of adhesion with only the minimum required clearance and materials.

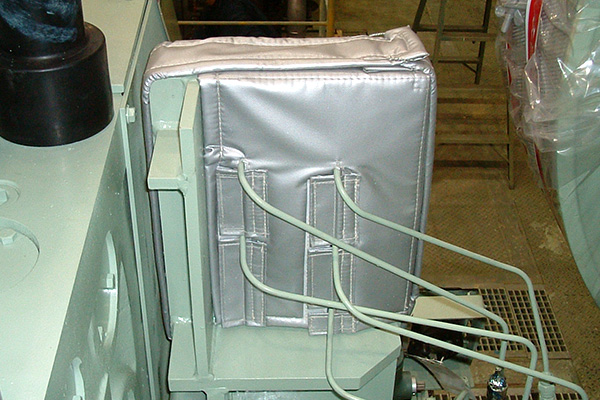

Also, it can be designed according to the shape of the parts and construction points so that it can be easily mounted and delivered as a molded product. This makes it easy for anyone to install and dramatically increases work efficiency.

The production data of molded products is managed collectively at our factory and we can handle maintenance and mass production smoothly.

As a result, installation by a specialized contractor is no longer necessary, contributing to cost reduction for users.

In this way, our lagging is a product, which contributes to the improvement of customers' Q, C, and D (Quality, Cost and Delivery).

Also, it can be designed according to the shape of the parts and construction points so that it can be easily mounted and delivered as a molded product. This makes it easy for anyone to install and dramatically increases work efficiency.

The production data of molded products is managed collectively at our factory and we can handle maintenance and mass production smoothly.

As a result, installation by a specialized contractor is no longer necessary, contributing to cost reduction for users.

In this way, our lagging is a product, which contributes to the improvement of customers' Q, C, and D (Quality, Cost and Delivery).

We can accept small orders for prototyping even if it is a single item request.

Please feel free to consult with us about the parts you have now or are planning. We can offer our services from the on-site installation work to molded product mass production.

We will propose a range of ideas for various locations, including joints, equipment, shiatsu valves, regulating valves, etc. and shapes that were in the past difficult to handle.

We will propose a range of ideas for various locations, including joints, equipment, shiatsu valves, regulating valves, etc. and shapes that were in the past difficult to handle.