TEMP SHIELD® is a detachable cover designed for heat and thermal insulation which keeps evolving while accumulating many achievements and utilizes our thermal insulation technology and know-how. TEMP SHIELD® has a wide range of materials, which can be used in various applications and temperature ranges, in addition to conventional thermal insulation materials.

By selecting and using the most suitable materials for each application, it will be more effective than conventional products (by our own calculations).

Thorough differentiation from other companies

We measure the target equipment directly and conduct thorough fact-finding on site. In addition, we also carry out type matching using the original pattern, so the customer can confirm the design images in advance of installation. Of course, it is always possible to change to the customer’s desired shape and specifications. By producing a shape which fits the customer’s equipment, it does not interfere with the customer’s everyday work.

We are devising TEMP SHIELD® detachable by field personnel, so that no special tools, skilled workers, or techniques are required to detach and re-attach TEMP SHIELD®.

In order to meet a wide variety of requests, we have launched with dozens of different types of materials. Any requests are welcome, so please feel free to contact us.

High repeat order rate and durability

In addition, in order to increase the durability of our products, we offer products with high durability and formability by applying nearly double the sewing processes compared to onventional products.

Implementation benefits and synergies

The benefits of TEMP SHIELD® are not only direct effects. Secondary effects, Tertiary effects and Synergistic effects can also be expected.

- Secondary effects: This includes improving the working environment through thermal insulation, reducing air conditioning costs due to a decrease in ambient temperature, reducing occupational accidents such as contact burns and reducing mechanical operating sound.

- Tertiary effect: TEMP SHIELD® can be used repeatedly by making it easy to attach and detach. It can be expected to reduce maintenance costs such as re-construction and it can be expected to be effective at various locations.

Safe and secure products & manufacturing plants

Our manufacturing plant has a production line dedicated to TEMP SHIELD®. Quality and environmental management are also thorough. (we have acquired ISO9001 and ISO14001)

In addition, through consistent production data management, we can smoothly respond to mass production, repeats, and corrections.

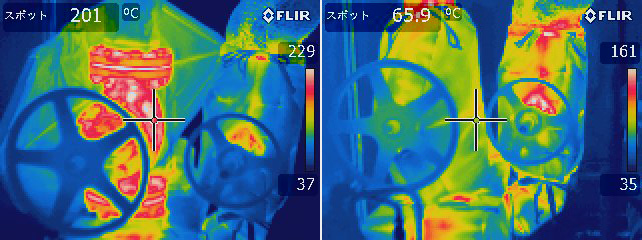

Possible to estimate and measure the effect of installation

For customers who would like to see the effect before and after the installation of TEMP SHIELD®, we use a thermography camera to perform comparative photography. Customers can see the temperature variations by the difference in color. These pictures can be used for internal reporting materials, etc. if required.

In addition, for customers who install TEMP SHIELD® as a power saving measure, we offer free rental of power measuring instruments and it is also possible to measure the actual amount of electricity consumed.

(We ask customers to install and measure power meters themselves.) Also, energy use diagnosis by experts is also possible (at an extra charge). Please consult us for further details.

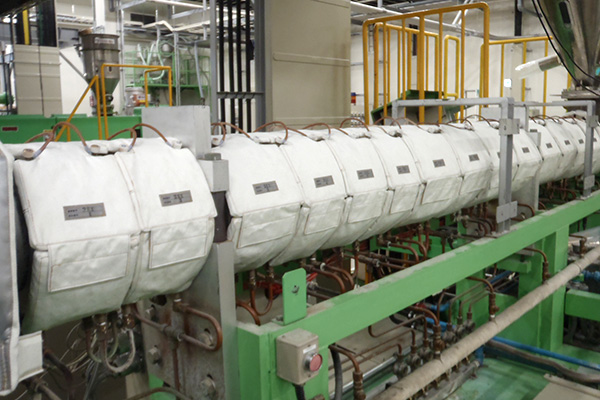

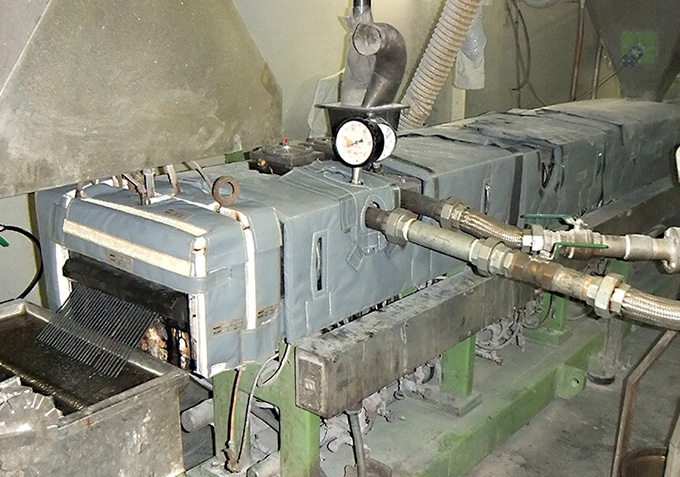

Installation examples

-

For reduction of replacement costs

In order to reduce replacement costs and take freezing measures, we introduced TEMP SHIELD® to a particular food factory in Kanto region, which solved the problem.

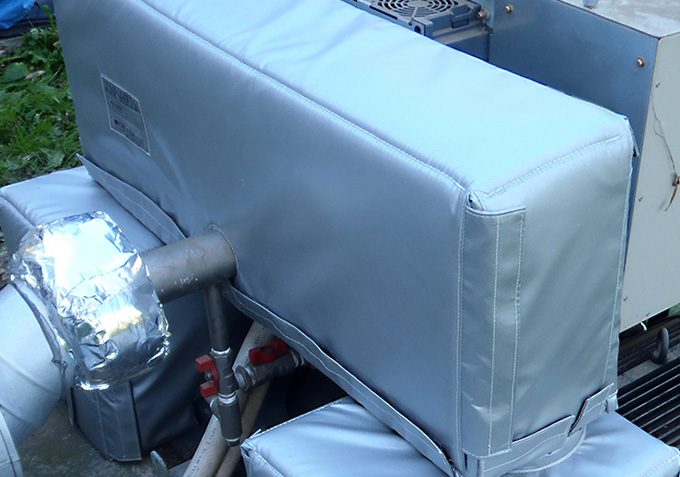

-

For reduction of labor and expenses

In order to reduce labor costs and to take countermeasures against condensation and freezing, we introduced TEMP SHIELD® to a certain paint manufacturer to solve the problem.

-

For efficient maintenance work

In order to improve the efficiency of maintenance work, we introduced TEMP SHIELD® to Naigai Special Engineering Corporations, which solved the problem.

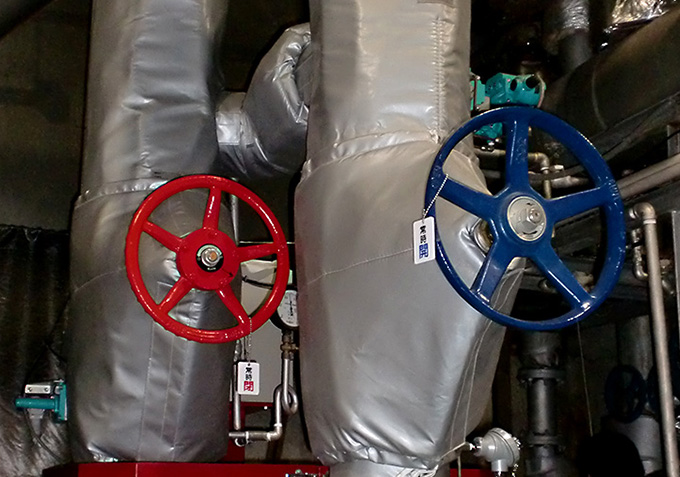

-

For energy saving and environmental measures.

We introduced a TEMP SHIELD® thermal insulation jacket to a plant in Osaka City for energy saving and environmental measures.