Cable shield

Robots and peripheral equipment at the manufacturing site are exposed to various threats such as friction, sparks, and chemicals.

Our cable shield is a high performance cloth cover, which protects the wiring/cables of robots and other equipment from such physical threats.

By preventing cable breakage, disruption caused by production line issues can be prevented and overall productivity can be improved and stabilized.

We have a wide variety of fabrics according to the application, so you can use them with confidence in various situations.

In addition, the removable design makes it easy to remove for the maintenance.

Since it is manufactured in-house, it is possible to respond to short delivery times and small batches.

Role of cable shield

- Cable protection from friction

Protects against friction generated when the main unit and the cable come into contact. - Cable protection from sparks

Protects against sparks generated during welding. - Protection from chemicals

Protects against strongly acidic chemicals and oil stains. - Protection from dirt

Protects against scattered particles and dust. - Bundle cables

Combining multiple cables stabilizes the operation and creates a neat and tidy appearance.

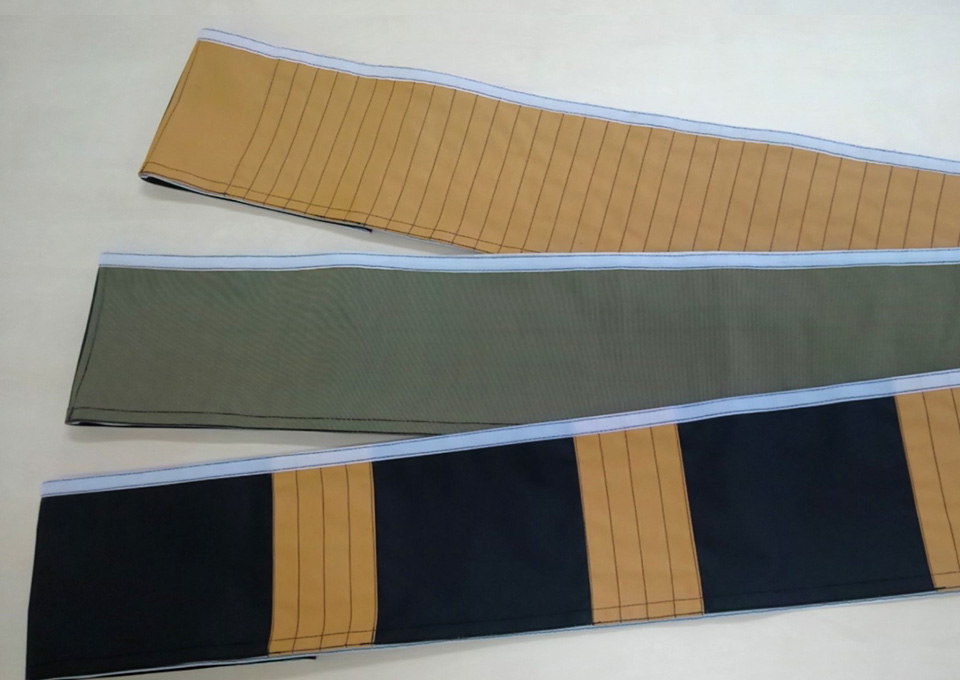

Example of cable shield product

Typical fabric types

- Meta-aramid fiber cloth

This fabric combines heat resistance, high strength, and electrical insulation. It comes in a range of colors. - PBO fiber cloth

It has the highest strength in the world among existing organic fibers. It has a decomposition temperature of 650℃, a limiting oxygen index of 68, and amazing heat resistance and flame retardant properties.

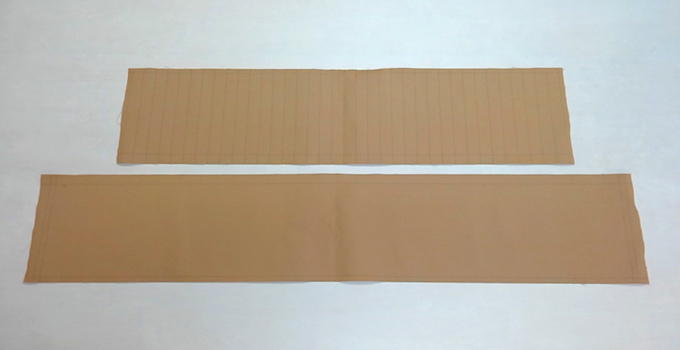

Meta-aramid fiber cloth color variations

PBO fiber cloth

【Data for various materials】

| LOI value | Tensile strength(N/5㎝) | Decomposition temperature(℃) | |

|---|---|---|---|

| Meta-aramid fiber cloth | 34.5 | 1811 | 400 |

| Para-aramid fiber cloth | 29~40 | 3860 | 500 |

| PBO fiber cloth | 68 | 6730 | 650 |

| PTFE film | 95 | ≧261 | 500 |

※The physical property values listed are not guaranteed values.

We also carry many other high strength and heat resistant fabrics.

Fabric combustion test (test method: JIS-L-1091)

Test material:Meta-aramid fiber cloth

LOI value (limit oxygen index): 34.5

Decomposition temperature: 400℃

Features: Flame resistance, heat resistance

Combustion test comparison material: Polyester

Combustion testing machine

Content

- Measures the extent of combustion spread, after exposure to flame and the residual time.

- Measures the spread of combustion on the sample surface.

- Measures the rate of sample burning.

Test video

Test results

- Meta-aramid fiber cloth

- Even after 2 minutes of heating, there is no residual flame or residue.

The carbonized area when heated for 1 minute is 6.6㎠. The carbonized area when heated for 2 minutes is 8.75㎠.

There was no flame after 2 minutes. -

- Polyester

- Flame begins to spread after 3 to 4 seconds, and fire takes hold after 10 seconds.

The flames broke out within a few seconds after igniting but burned out almost instantly. -