ROBOT SHIELD for FANUC CRX series

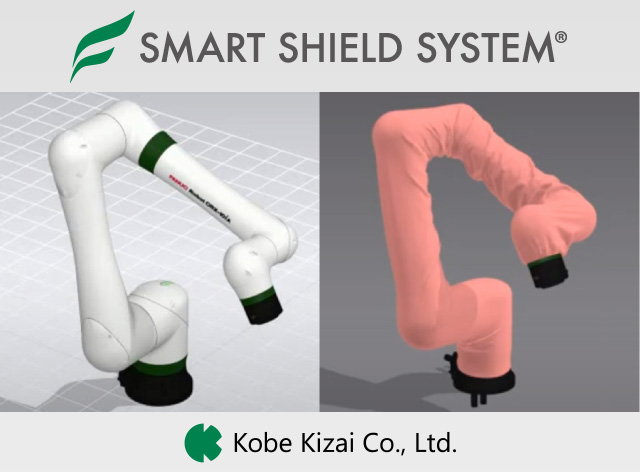

Protective cover for collaborative robots manufactured by Kobe Kizai

Exclusive cover protects your robot without loss of functionality.

Customization is also easy to order.

FANUC CRX robots are active in the industrial scene and are always required to operate safely and reliably.

Our ROBOT SHIELD for CRX is designed with the idea of “Avoiding disturbance of customer’s work” in mind, to ensure more safe and reliable operation of CRX for a long time.

We offer “semi-custom order system” with easy customization options suitable for your production line, such as selecting materials based on the operating environment of CRX or adding protectors for peripheral cables attached. Please contact us for more information.

Features of ROBOT SHIELD

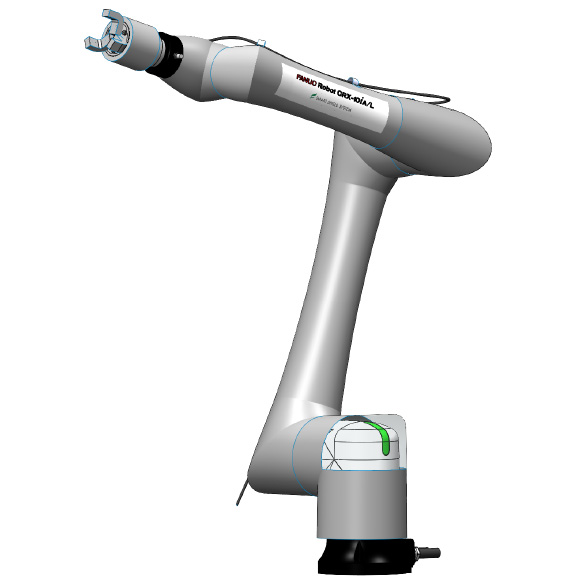

Sophisticated design fits CRX

ROBOT SHIELD is designed based on detailed motion simulation using a proprietary 3D model. So, it is possible to protect your CRX without hindering its movement and operability.

Product image (gray)

Product image (black)

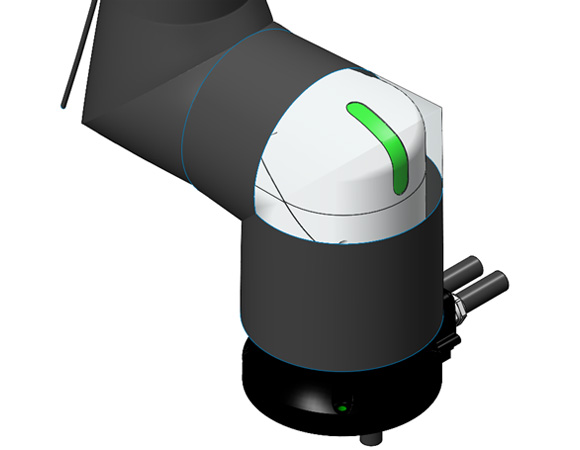

Easily detachable

ROBOT SHIELD can be detached from the side of the robot with hook-and-loop fastener.

Maintenance can be finished in a short time and the production line can be restored immediately.

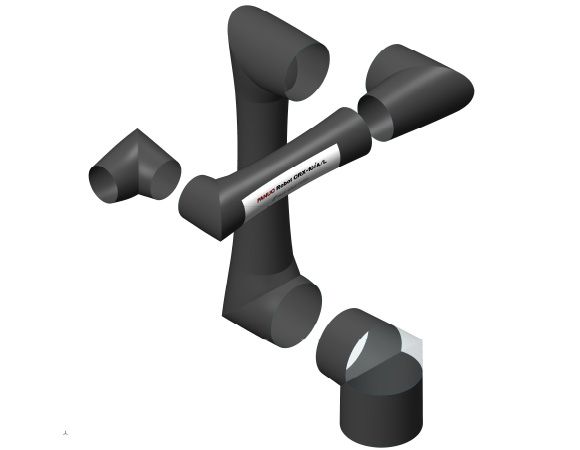

Prevent interference with the robot’s operation

ROBOT SHIELD is split near the rotation axis and moves smoothly according to the robot's movement.

Quickly check the operation status

We adopt translucent materials for the cover parts around the robot LED indicator, and you can quickly check the status without removing the cover.

The parts replacement is available

We also provide replacement parts, if necessary.

Optional Accessories

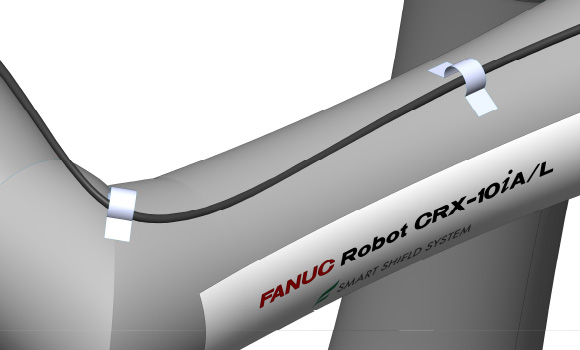

CABLE SHIELD

Cables connected to robots can sometimes wear out and break due to friction during robot operation. By using CABLE SHIELD, it is possible to bundle the cables and protect them from rubbing against the robot body. We offer CABLE SHIELD suitable for the cables in your production line. And customization of ROBOT SHIELD is also available.

Cable Wiring Guide

To minimize damage to the cables connected to the robot, it is necessary to fix them in the correct position. Passing the cables through the Cable wiring guides can make it possible to minimize damage to the cables and keep them looking neat. The number and position of the guides can be customized to suit your robot operating site.

CABLE SHIELD Size List

| Diameter of a cable (mm) | Length (mm) |

|---|---|

| Φ10, 20, 30, 40, 50, 60, 80, 100, 150, 200 | 500, 700, 900, 1000, 1500, 2000 |

※Please contact us, if you need the size other than those listed above.

Fabric Material List (for an example)

We can select the best material for your CRX robot’s operating environment.

| Material types | Colors | Features | Usages |

|---|---|---|---|

| Aramid fiber | Black or Gray | ・Excellent heat resistance and tensile strength, and can be color coated | ・For sites with spatter flies ・For robots with large movement |

| 100% polyester | White | ・Non-PVC, complies with the Food Sanitation Act (in Japan) | ・For use in food factories |

| 100% PTFE film | Translucent | ・Excellent chemical and water resistance, and complies with the Food Sanitation Act (in Japan) | ・For use in food factories or clean rooms |

| PBO fiber | Orange | ・The highest class of strength and flame resistance among organic fibers | ・For protecting robots from sharp objects |

| 100% polyethylene film | White | ・Excellent water and chemical resistance, and fabric-like soft structure suitable for three-dimensional sewing | ・For sites where chemicals are scattered |

| 100% polyester knit | Green | ・Lightweight with excellent stretch and water repellent, wide variety of colors | ・For joints with large twists and bends |

3D model animation

When we began the basic design of ROBOT SHIELD, we set our goal to achieve “protection without compromising the functionality and aesthetics of a robot”. In other words, what ROBOT SHIELD needed was to protect a robot from external interference without hindering its movement, minimize various costs (such as maintenance costs) associated with attaching the protective cover, and keep the functional beauty of a robot in a customer's production line. We wanted to accomplish all these aspects.

So first, to thoroughly simulate the 3D movements of a robot, we developed our unique ROBOT AVATAR. By testing the avatar equipped with the prototype protective cover in the design process, we had eliminated visualized interactions and problems one by one to approach the optimal shape of the cover. After this work, we had finally established the basic design of ROBOT SHIELD. In addition, in terms of options that fit a customer's production line, we made it possible to realize a low-cost “semi-custom order system” that can be completed by verifying in virtual space using avatars.

For many years, we have been manufacturing robot cable protective covers for multi-variety and small-batch production. We have also been making thermal insulation covers of full-customization for ages. We have combined our expertise to build up “semi-custom order system”. We sincerely hope that our ROBOT SHIELD will be useful for your robots and production line.